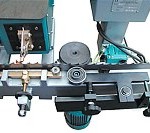

Band saw tooth tip hardening machine Type BHM 80

Heating occurs in a continuous process. A cooling water system is required for cooling the generator or inductor that heats or hardens the teeth.

- There are 3 possibilities for this:

- Direct connection to the water main at a pressure of 3 bar. Only to be recommended if the water is not too cold and the price of water is low.

- Cooling unit that cools down the heated water during operation and returns it to the generator with the help of a pressure pump (operating pressure 3.5 – 4 bar expensive solution).

- Cost-effective solution

1 water tank with a content of ca. 450 litres with a pressure pump 3.5 – 4 bar fitted with an adjustable temperature probe that controls a solenoid valve feeding fresh water from the mains. For an 8-hour day and normal daytime temperature the amount of water used is approx. 60 litres. The heated water then runs off via an overflow into a drain or can be collected for other purposes.

Note: The water is used for cooling only and is not contaminated.

Technical data:

| Dimensions: | Width: 230 cm |

| Depth: 75 cm | |

| Height: 130 cm | |

| Total power: | approx. 3 kW |

| Water flow: | (Inductor) approx. 2.5 litres/min. |

| Drive power: | Band saw feed (friction drive) steplessly adjustable via gear motor |

| by means of a potentiometer | |

| Winder unit: | via slipping clutch with gear motor drive |

| Generator power: | 2 kW for the Himmel generator HG 34 shown |

| Weight: | 205 kg |

| Operating voltage: | 230/400 Volt, 3 Phase, 50 cycles or |

| 230/440 Volt, 3 Phase, 60 cycles | |

| Other voltages via a transformer | |

| Note: | All types and makes of generator from 2-6 kW with cable outlet |

| can be used, heating capacity 40-50 teeth/min. | |

| Tube generators are better suited for this purpose. Electronic converters or generators are only partly suitable for the purpose of the operating time. |